Design considerations for building Quadcopters

Trials and Tribulations

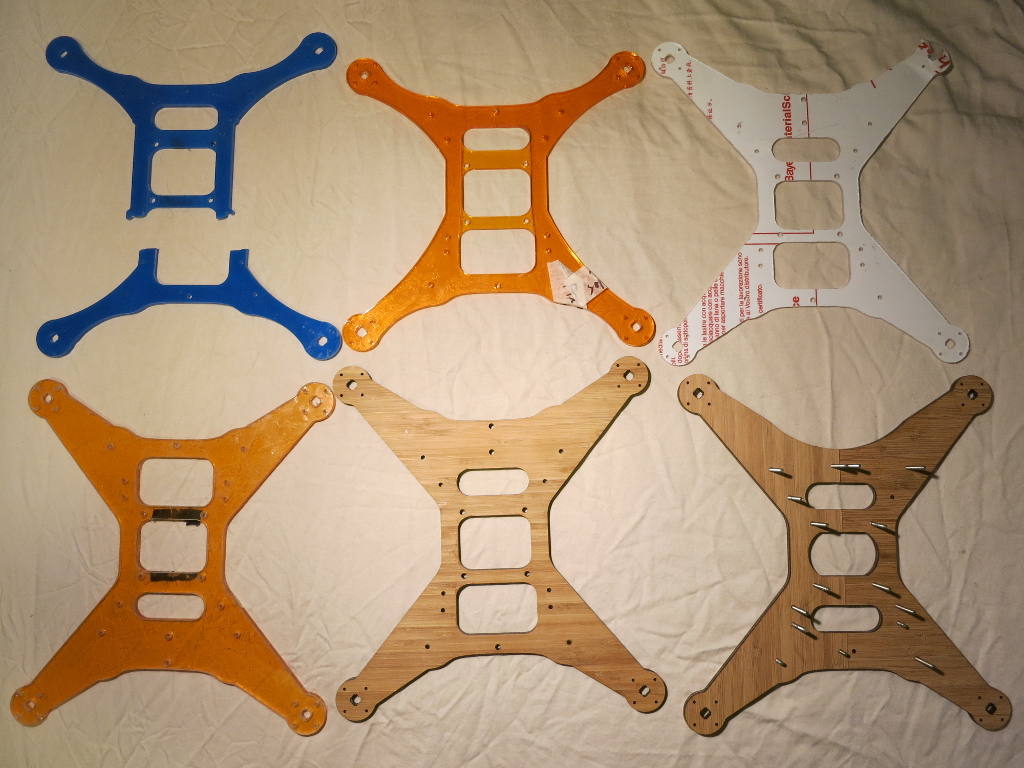

From the image above you can see 6 different iterations of this quadcopter design. From the top left to the bottom right you can see the change in materials and design modifications. This is by no means a comprehensive list of different iterations. This is just what I found lying around at home. The following are some of the design considerations.

Materials

I have been experimenting with many different materials, my primary concerns are weight, flexibility/rigidity and strength.

At first I experimented with Acrylic, which is very easy to lasercut and I happen to have access to a laser cutter, so for my purposes this was the best material to prototype with. Acrylic is quite expensive compared with other materials such as Polycarbonate or plywood but my main issue was it was so brittle. I have had many light crashes where the frame just snapped in two. I fly quadcopter quite a lot, so I am very used to crashes and having them break, however the frames need to be more resilient to light crashes and general hard landings.

Next, I tried polycarbonate, this material is used in bullet-proof glass. It is heavier than acrylic and also surprisingly flexible I could bend it back on itself.

This material also had to be water-jet cut as laser-cutting caused all sorts of toxic fumes to come out, and this process is so much more costly.

As my search continued, I started to look at different types of plywoods. I first had started on marine ply which is very toxic to lasercut but readily available. Marine Ply is quite heavy, very strong and waterproof. It was however too heavy for my applications but was very interesting to play around with. While looking at ply I came across bamboo ply which fulfils most of my criteria. Its very light, cheap and quite strong. This is what I have been designing with more recently and its been very nice to work with, although The strength is not as good as I would have liked and I have had to reinforce it in places to make sure it does not snap.

Weight vs Flexibility/Rigidity

Weight is the most crucial design consideration as it effects the flight characteristics. If its too heavy it may be too heavy to take off. There is also a polynomial relationship between weight and flight time.

Flexibility is important in quadcopter design because it needs to be able to absorb impacts such as crashes or hard landings. Impacts happen all the time. While some crashes will be fatal no matter how good the design is, often, the damage can be mitigated by good landing legs, and a frame designed to absorb the impact. As well as absorbing the impact, you want to have some flex to reduce vibration issues.

Acrylic was a good example of what not to use - every time I landed even lightly it would crack or shatter the frame. This could not be mitigated by legs because the material was just too brittle and did not have enough flex.

Material Properties in Summary

Acrylic

- Light

- Cheapish

- Brittle

Polycarbonate

- Heavier than acrylic

- Incredibly strong

- Cheaper that acrylic

- Too flexible at 3mm thickness

Plywood

- Strong

- Cheap

- Heavier that Acrylic

Bamboo Ply

- Light

- Strong but not as strong as normal plywood, needs to be reinforced

- More flexible than Acrylic

- Bit more expensive than normal plywood

Carbon Fibre

- Light

- Strong

- Expensive

- Hard to cut

- On crashing shatters really badly.

Conclusion

I hope that has given quick overview of design considerations going into building a quadcopter and rapid prototyping.